100ºC Isıtma Kapağına Sahip Yüksek Hızlı Döndürme Kaplama Makinesi

VTC-100PA-I Vakumlu Spin Kaplayıcı, yarı iletken prosesleri, kristal, optik disk, plaka yapımı ve yüzey kaplama vb. için uygundur. Güçlü asit ve güçlü alkali kaplama çözeltileri için kullanılabilir. Cihaz, numune boyutuna göre farklı boyutlarda (standart olarak) iki vakumlu kaplayıcı ile donatılmıştır. Cihaz 12 program seti saklayabilir ve her set 6 çalışma aşaması içerir.

- Shenyang Kejing

- Shenyang, Çin

- 10 iş günü

- 50 set

- bilgi

Ürün Tanıtımı

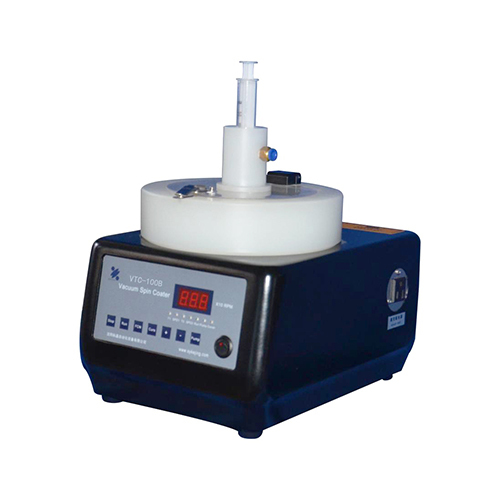

VTC-100PA-I Vakumlu Spin Kaplayıcı, yarı iletkenler, kristaller, optik diskler ve fotolitografide yüzey kaplama işlemleri için tasarlanmıştır. Güçlü asit veya alkali çözeltiler kullanarak kaplama hazırlamak için uygundur. Sistem, farklı boyutlarda iki standart vakumlu kaplayıcıyla birlikte gelir ve kullanıcıların numune boyutlarına göre uygun kaplayıcıyı seçmelerine olanak tanır.

Çalışma sırasında numune, vakumlu bir mandreyle numune tablasına güvenli bir şekilde sabitlenir. VTC-100PA-I, her biri 6 ardışık adımdan oluşan 12 adede kadar program saklayabilir. Dönüş hızı farklı tablalar arasında değişerek cihazın kademeli olarak maksimum hızına ulaşmasını sağlar. Bu sayede numune yüzeyinde homojen ince film oluşumu sağlanır, malzeme israfı en aza indirilir ve verimlilik artar.

VTC-100PA-I, basit kullanım, kolay temizlik ve kompakt bir tasarıma sahiptir. Üniversite ve araştırma enstitülerinin laboratuvarlarında ince film biriktirme prosesleri için yaygın olarak kullanılmaktadır.

Ana Özellikler

1. Numune, çalıştırılması kolay olan vakum adsorpsiyonu yoluyla sabitlenir.

2. Vakum derecesi -0.08MPa'ya ulaşabilir.

3. Konumlandırma aracı kullanılarak numuneler kolayca ortalanabilir ve hizalama hatasından kaynaklanan titreşim veya fırlamalar azaltılabilir.

4. Numune özelliklerine göre farklı mandrenler kullanılabilir ve değişimi kolay ve basittir.

5. 24V fırçasız DC motor kullanılmıştır ve yüksek güvenilirlik, güçlü uyarlanabilirlik, basit onarım ve bakım, düşük gürültü, küçük titreşim, kararlı çalışma, hızlı ve kararlı başlatma, hızlanmadan sonra kararlı çalışma avantajlarına sahiptir, kaplama kalınlığının tutarlılığını ve düzgünlüğünü sağlar.

6. Yağsız paralel çubuk vakum pompasının küçük boyut, basit yapı, kolay kullanım, rahat bakım ve çevre kirliliği yaratmama avantajları vardır.

7. Hazne, kimyasal korozyona ve mükemmel stres çatlağına karşı direnç yeteneklerini artırmak için daha uzun hizmet ömrüne sahip polipropilen malzemeden yapılmıştır ve makine gövdesi, dayanıklı ve hafif olan döküm alüminyum yapıyı benimser.

8. Kaplama işlemi inert gaz atmosferinde (Ar, N2 gibi) yapılabilir.

9. İngilizce işletim sistemi

10. Açık kapak koruma fonksiyonuna sahiptir. Kaplama işlemi sırasında veya kaplamanın sonunda üst kapak açıldığında, makine aniden ve hızla yavaşlayarak durur.

11. Kontrol arayüzü dokunmatik ekran ve tek kartlı bilgisayar kontrol sistemini benimser ve sayısal ekran daha sezgisel ve güvenilirdir.

Tteknik Parametreler

Ürün Adı | VTC-100PA-I Vakumlu Döndürme Kaplama Makinesi | |

Ürün Modeli | VTC-100PA-I | |

Kurulum Koşulları | 1. Sıcaklık ve Nem: %10–85RH (25°C'de, yoğuşmasız); Çalışma sıcaklığı: 0–45°C. 2. Ortam: Güçlü titreşim kaynaklarından ve aşındırıcı gazlardan uzak. 3. Su: Drenaj çıkışı ile donatılmıştır. 4. Güç Kaynağı: Tek fazlı AC220V 50Hz 10A. 5. Gaz: Vakum (negatif basınç) ve pompalama hızı ≥70 L/dak; sisteme koruyucu inert gazlar (örneğin Ar, N₂) da bağlanabilir. 6. Çalışma tezgahı: Önerilen boyut 800 mm × 600 mm × 700 mm, yük kapasitesi ≥50 kg (tercihen sağlam beton masa). 7. Havalandırma: Özel bir gereksinim yoktur. | |

Ana Parametreler (Şartname) | 1. Güç Kaynağı Arayüzü: · Ana Ünite: AC220V 50Hz 10A · Isıtma: AC220V 50Hz 10A 2. Toplam Güç Tüketimi: ≤1150W (harici vakum pompası hariç) 3. Kaplama Odası (Malzeme): Polipropilen 4. Numune Tutucu (Vakumlu Mandren): PTFE vakumlu mandrenler, Ø19 mm ve Ø60 mm (her birinden bir tane) 5. Çalışma Modu: 12'ye kadar programlanabilir tarif; her tarif 6 ardışık aşama içerir 6. Sıkma Hızı Aralığı: 500–10.000 rpm (etkili) 7. Hızlanma/Yavaşlama Oranı: Kademe başına 100 rpm ile 2000 rpm arasında ayarlanabilir 8. Kaplama Süresi: Aşama başına 0–60 saniye 9. Hız Sabitliği: ±1% 10. Kontrol Sistemi: Tuş takımı kontrolü ve LMC LCD ekranlı PCB mikrodenetleyici 11. Isıtma Yöntemi: Bağımsız karbon fiber ısıtma borusu sistemi (ana ünite kontrolünden ayrı) 12. Isıtma Sıcaklık Aralığı: Oda sıcaklığı ile 100°C arası 13. Isıtma Gücü: AC220V, 1000W 14. Sıcaklık Kontrol Doğruluğu: ±2°C | |

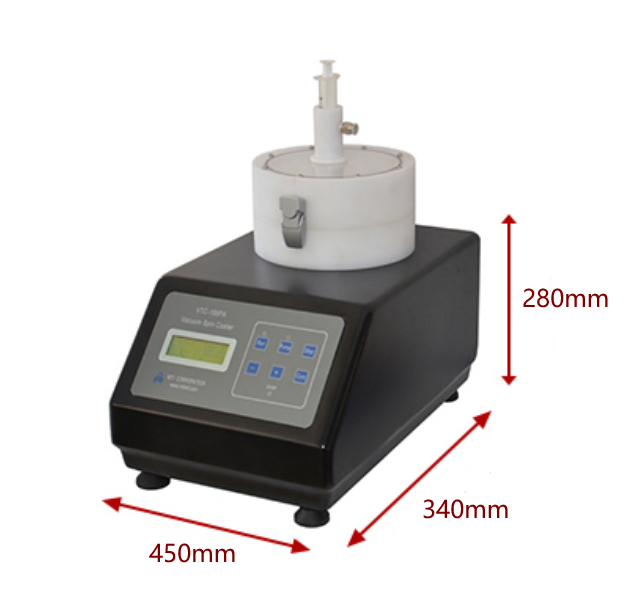

15. Ürün Özellikleri: · Boyutlar: 450mm×340mm×280mm · Ağırlık: 20kg |

| |

Sstandart Aksesuarlar

HAYIR. | isim | miktar | resim |

1 | Vakum Mandren (O-ring dahil) (Ø19mm VeØ60mm) | 2 adet |

|

2 | Merkezi Konumlandırıcı/Konum Belirleyici (4 konumlandırma saplaması dahil) | 1 adet |

|

3 | Epoksi Enjektör/Şırınga (20ml) | 1 adet | |

4 | Enjektör/Şırınga Braketi | 1 adet | - |

5 | Yağsız Vakum Pompası | 1 adet |

|

6 | Kauçuk Boru (kelepçe dahil) | 1 adet | - |

OOpsiyonel Aksesuarlar

HAYIR. | isim | fonksiyonel tip | resim |

1 | Diğer özelliklerdeki Vakumlu Mandrenler | (isteğe bağlı) | |

2 | Pipet (Çin malı) | (isteğe bağlı) | |

3 | Pipet (ithal) | (isteğe bağlı) |

|

Garanti

Ömür boyu destekle sınırlı bir yıl (yetersiz depolama koşulları nedeniyle paslanan parçalar hariç)

Lojistik